- +27 18 293 2854

- +27 82 558 9810

- [email protected]

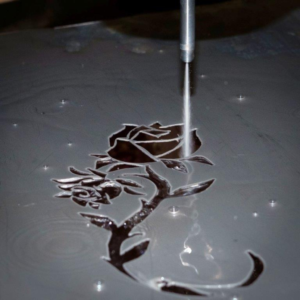

Advanced Waterjet Cutting

Stone Dynamics opened a Water Jet cutting department when we acquired a water jet in 2021. This department enhanced our manufacturing capabilities and options.

The Abrasive water jet is able, when an abrasive material is added to the high-pressure water, to cut hard substances.

The water jet uses water, forced at high pressure through a nozzle at about Mach 3 to cut materials. The water jet also cuts accurate to 0.13mm of precision. It can accommodate materials to be processed up to a size of 3400 x 1600mm.

The water jet is managed by CNC technology. The 3-axis head can be used to cut contours on various surfaces.

Many materials can be cut by an abrasive water jet such as: Textiles, rubber, foam, plastics, leather, composites, stone, tile, glass, steel, metal and ceramics (as long as the abrasive material used is harder than the ceramic). The water jet is not able to cut diamonds and tempered glass. The water jet has additional advantages that no heat and /or dust are

produced during the cutting process.

At Stone Dynamics the water jet’s ability to cut so precise and with minimal waste, we can cut intricate inlays in most materials.